It will be important firstly to choose the lining material and to familiarise yourself with the lining board manufacturer's recommendations on what is suitable for different environments, together with the best most appropriate fixing methods.

It’s no good choosing a 6mm fibre cement board screwed up to a concealed ceiling system and after ensuring the framing is both secure and rigid enough to withstand the likely wind loadings, only for the wind to ‘suck’ the 6mm lining board off the countersunk screws used to secure it to the framing. There have been examples where the use of 9 or 12mm board would have prevented the problem from occurring.

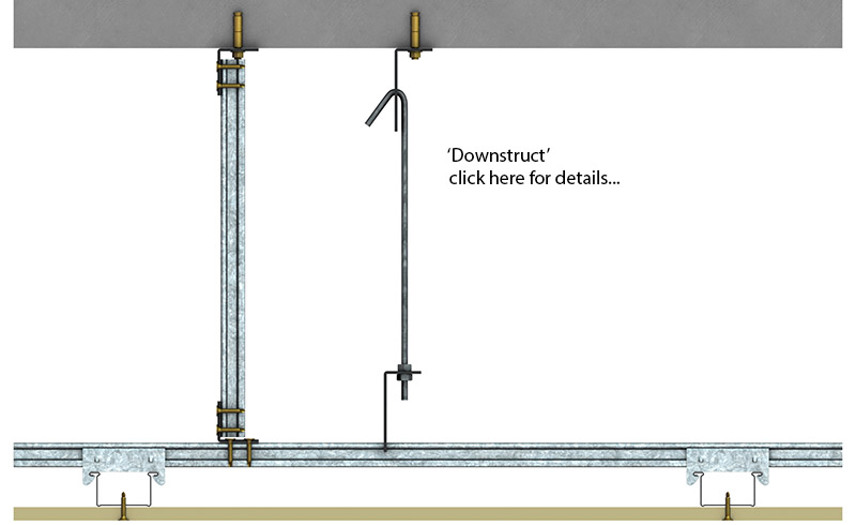

Down strutting in external ceilings

Similarly, its important to understand the role of ‘down strutting’ which is to provide suitably rigid bracing between the framing members and the structure. Without solid down strutting, the upward force exerted by high wind pressures can cause a badly installed suspended ceiling to ‘cave in’ and ultimately collapse. In this example, not only is the lining material destroyed but the ceiling framing as well.

The downstrut acts in compression under an upward wind load and therefore nominal fixings are required at either end, as shown in our KEY-LOCK® Concealed Ceiling System Manual along with a host of other design information, including ultimate load capacities.

Steel Studs for Ceiling Systems

In areas of potentially high wind loads it may be that more solid systems are required for such framing such as the use of steel studs as joists. More information on using our Steel Studs for Ceilings can be found here, however it should be noted that when ceilings are external, they should be checked by us or a structural engineer prior to work starting.

What environment will the ceiling be installed in?

We touched earlier upon the environment the soffit might be installed in, close to salt water being a case in point.

Say the local surf club wants to line the underside of the roof over their beach facing balcony to turn it into an outdoor eating area. Not only is the wind going to be a critical factor but the proximity to breaking surf will present more problems, that of a corrosion hazard to the steel framing.

Now it could be argued that the lining board once installed, taped and set would form an impenetrable barrier to salt laden moisture getting to the steel framing but moisture can be difficult to keep out.

If steel is the material of choice then not only should the potential to have heavier galvanising specified for the components be considered, but once the framing is installed and before the linings are applied the whole framing system should be liberally painted with a rust preventative. But remember, like most things close to the ocean, a regular inspection and preventative maintenance program should be followed.

Where you can get help

External ceilings are exposed to harsher conditions than those that are located internally. There must be careful consideration for the environment it’ll be in to provide additional protection from the elements. Like us, lining manufacturers CSR and USG Boral, have the literature and technical assistance available to help you to produce a safe, serviceable, and acceptable job, so make sure you speak with them prior to the commencement of work.

At Rondo, we have Product Manuals you can download, or simply send our Technical Team an enquiry about your external ceiling today!