Rondo MAXIframe® External Wall Framing System offers a more efficient, versatile and cost effective design option than traditional external wall framing.

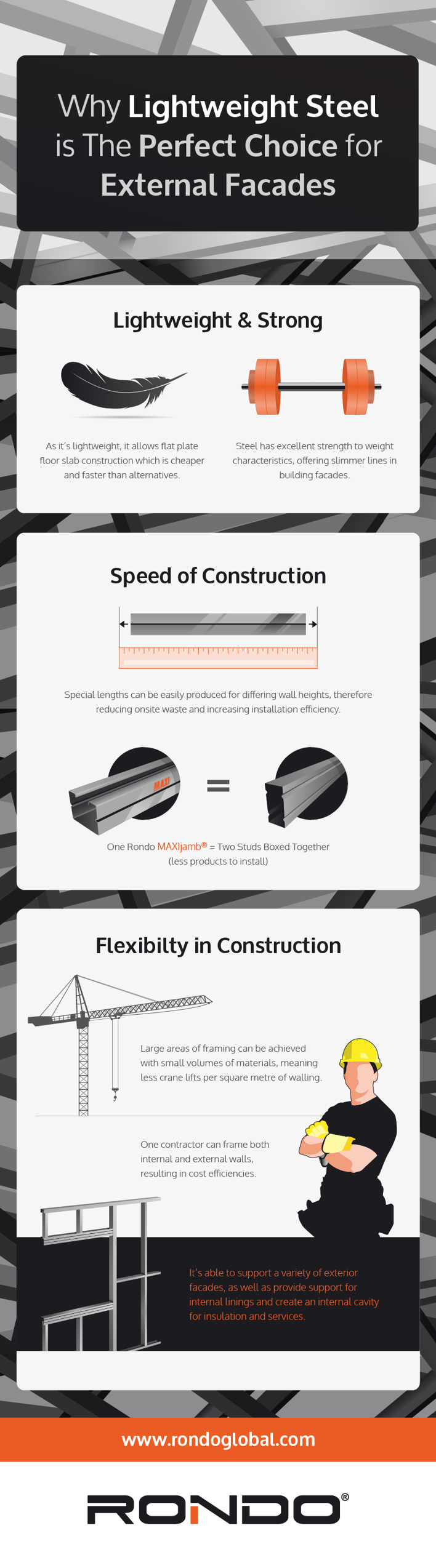

LIGHTWEIGHT AND STRONG

Steel has excellent strength to weight characteristics, offering slimmer lines in building façades. As it’s lightweight, it allows flat plate floor slab construction which is cheaper and faster than alternatives

SPEED OF CONSTRUCTION

Special lengths can be easily produced for differing wall heights, therefore reducing onsite waste and increasing installation efficiency

One Rondo MAXIjamb® equals two regular Steel Studs boxed together. With less products to install, significant labour cost savings can be achieved in a project

DURABILITY

Steel coating type and thickness can be changed to accommodate site environmental conditions (Z275).

FLEXIBILITY IN CONSTRUCTION

Large areas of framing can be achieved with small volumes of materials, meaning less crane lifts per square metre of walling

It’s able to support a variety of exterior facades, as well as provide support for internal linings and create an internal cavity for insulation and services. One contractor can frame both internal and external walls, resulting in cost efficiencies for the project

DESIGN CONSIDERATIONS:

The seismic load on the building is directly proportional to the mass of construction, making lightweight steel a good option in seismic applications. I.e. low weight = low seismic load.

Light weight steel is 80% lighter than a wet block work system. It's dry construction, there's no curing time and no wet trade required.

FLEXIBILITY IN DESIGN

Able to support a variety of exterior facades, e.g. brick veneer, AAC panels, lightweight cladding or panel systems. Also providing support for internal linings plus create an internal cavity for insulation and services. Designs can be tailored to wind conditions in specific regions and urban environment. Light weight steel provides an opportunity to increase its strength with high tensile steel eg. Sill & Header, Jamb Stud profiles are increased to G500 where loads are critical.

PROJECT CASE STUDY

Rondo supplied the MAXIframe® System to the Sunshine Coast Hospital Project where it was determined that the initial design using standard 150mm back to back stud configuration located at 300mm centres was not going to be an economical solution or able to meet the window design requirements.

Rondo was brought in to offer an alternative solution and they produced a special 150mm Jamb Stud in 1.2bmt, G500 material which could achieve wall heights of 4.1m and meet wind load requirements. It could also be spaced at 675mm centres to suit the window modules